Choosing the right footwear is a critical, often underestimated, aspect of an electrician’s daily safety and efficiency. The demanding nature of the profession, which frequently involves working in close proximity to electrical hazards, necessitates boots that not only offer robust protection but also exceptional comfort and durability. This is where identifying the best work boots for electricians becomes paramount, as substandard footwear can compromise safety protocols and lead to significant physical strain over prolonged periods. A thorough understanding of the specific requirements of electrical work, such as dielectric protection and slip resistance, is essential for making an informed purchase that directly impacts job performance and well-being.

This comprehensive guide aims to equip electricians with the knowledge needed to select the ideal work boots for their profession. We delve into the key features that differentiate suitable footwear, from the materials used in construction to specialized safety certifications. Through in-depth reviews of leading brands and models, we highlight the performance characteristics that matter most, including shock absorption, ankle support, and breathability. By examining the nuances of various boot designs and their applications, this article serves as an indispensable resource for any electrician seeking to invest in footwear that guarantees both safety and productivity on the job.

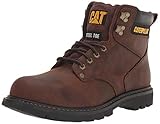

We will discuss the best work boots for electrician further down, but for now, consider checking out these related items on Amazon:

Last update on 2025-12-03 / Affiliate links / #ad / Images from Amazon Product Advertising API

Analytical Overview of Work Boots for Electricians

The demand for specialized work boots for electricians is driven by the inherent risks of their profession, particularly the potential for electrical shock. This has led to a significant focus on safety features, with electrical hazard (EH) rated boots becoming a non-negotiable standard. These boots are designed with non-conductive soles and heels to provide a secondary layer of protection against live circuits, a critical feature for any professional working with electricity. Manufacturers are increasingly investing in advanced materials and construction techniques to enhance both safety and durability, recognizing that electricians often operate in demanding environments where exposure to moisture, chemicals, and rough terrain is common.

A primary trend in this market is the integration of comfort and performance without compromising safety. While EH rating is paramount, electricians also spend long hours on their feet, necessitating boots that offer superior cushioning, arch support, and breathability. This has led to the incorporation of technologies like memory foam insoles, moisture-wicking linings, and breathable waterproof membranes. Furthermore, the pursuit of lighter yet equally protective materials is ongoing. For instance, advanced composite toe caps are replacing traditional steel toes in many models, offering comparable impact protection with a significant reduction in weight, thus alleviating foot fatigue.

The benefits of selecting the correct work boots for an electrician extend beyond mere compliance. Proper footwear significantly reduces the risk of severe injury from electrical accidents. Beyond electrical safety, well-designed boots contribute to overall physical well-being by preventing common workplace injuries like slips, trips, and falls, and reducing the likelihood of foot and ankle pain. The durability of high-quality boots also translates to cost savings over time, as they require less frequent replacement compared to inferior alternatives. Ultimately, investing in the best work boots for electricians is an investment in personal safety, comfort, and long-term health.

Despite advancements, challenges remain. The cost of high-quality, EH-rated boots can be a barrier for some individuals, though the long-term safety benefits often outweigh the initial investment. Maintaining the integrity of the EH rating is also crucial; damage to the soles or stitching can compromise their protective capabilities, requiring regular inspection and, if necessary, replacement. Furthermore, the vast array of available options can make it difficult for consumers to identify the truly superior products that meet their specific needs and working conditions, highlighting the importance of thorough research and understanding of industry certifications.

Top 5 Best Work Boots For Electrician

Timberland PRO Men’s Direct Attach 6″ Steel Toe Waterproof Boot

This boot offers a robust combination of safety and durability, crucial for electricians. The steel toe cap meets ASTM F2413 protective toe classification, providing reliable impact and compression protection. Its electrical hazard (EH) protection further enhances safety, rated to guard against open circuits up to 18,000 volts. The waterproof nubuck leather upper, combined with a seam-sealed construction, ensures dryness in wet work environments, a common occurrence on job sites. The lugged rubber outsole provides excellent traction on various surfaces, minimizing slip risks, while the direct-attach construction enhances waterproofness and longevity by fusing the upper to the sole.

Performance-wise, the boot excels in comfort and support throughout extended wear. The padded collar and tongue offer a snug fit and prevent chafing, while the thermoplastic urethane (TPU) rubber lug outsole offers excellent abrasion resistance and stability. The polyurethane midsole provides cushioning and shock absorption, reducing foot fatigue during long shifts. While the initial cost may be higher than some competitors, the combination of high-quality materials, comprehensive safety features, and expected long lifespan offers strong value for electricians who prioritize protection and reliability in their footwear.

Wolverine Floorhand 6″ Steel Toe Waterproof Work Boot

The Wolverine Floorhand boot is engineered with an emphasis on protection and comfort for demanding work. It features a steel toe cap that conforms to ASTM F2413 standards for impact and compression resistance. Crucially for electricians, this boot also provides Electrical Hazard (EH) protection, rated to safeguard against open electrical circuits, a vital safety component in this profession. The waterproof full-grain leather upper, coupled with a waterproof membrane, ensures that feet remain dry and comfortable in damp conditions, preventing the discomfort and potential safety issues associated with wet footwear.

The design prioritizes sustained comfort and performance. The removable, dual-density cushioned footbed offers substantial support and shock absorption, helping to mitigate foot fatigue over extended periods. The rubber slip-resistant outsole delivers reliable grip on various surfaces, reducing the risk of slips and falls. The Goodyear Welt construction contributes to the boot’s overall durability and allows for resoling, extending the boot’s service life. Considering its blend of protective features, comfort-oriented design, and the potential for extended use through resoling, the Wolverine Floorhand presents a compelling value proposition for electricians.

Irish Setter 83602 6″ Aluminum Toe Work Boot

This Irish Setter model offers a lighter alternative for electricians while maintaining essential safety standards. It features an aluminum toe cap, meeting ASTM F2413-18 M I/75 C/75 EH standards, providing significant toe protection with reduced weight compared to steel. The boot’s Electrical Hazard (EH) rating is a critical feature, offering protection against open electrical circuits. The full-grain leather upper is designed for durability and breathability, while the rubber sole ensures dependable traction, a necessity for navigating diverse work environments safely.

The performance of the 83602 is characterized by its comfort and stable footing. The EVA midsole offers cushioning, absorbing impact and contributing to all-day comfort. The rubber lug outsole provides excellent grip on various surfaces, enhancing stability and reducing the risk of slips. The direct-attach construction promotes waterproofness and durability. For electricians seeking a balance between robust protection, reduced weight, and reliable comfort, this boot offers excellent performance and a competitive value, particularly for those who experience significant walking or climbing during their workday.

KEEN Utility Men’s Pittsburgh 6″ Steel Toe Waterproof Boot

The KEEN Utility Pittsburgh is a high-performance boot designed for demanding electrical work environments. Its steel toe meets ASTM F2413-18 I/75 C/75 standards for impact and compression protection, and importantly, it carries an Electrical Hazard (EH) rating for protection against open circuits. The waterproof nubuck leather upper, treated with a KEEN.DRY proprietary waterproof breathable membrane, ensures that feet remain dry and comfortable in various weather conditions and on wet job sites.

The boot’s design focuses on ergonomic support and durability. It features an internal support mechanism that aids in midfoot support, reducing fatigue during long hours. The oil- and slip-resistant rubber outsole provides excellent traction on a multitude of surfaces, a critical safety factor for electricians. The KEEN Luftcell polyurethane (PU) midsole offers advanced cushioning and energy return, enhancing comfort and reducing the impact on feet. The KEEN.PROTECT toe bumper adds an extra layer of durability against abrasion. This boot represents a strong investment for electricians due to its comprehensive safety features, advanced comfort technology, and robust construction designed for extended wear.

Danner Vicious 8″ Non-Metalic Toe NMT Work Boot

The Danner Vicious work boot is engineered with specific considerations for electricians, particularly those who require non-metallic safety features. It boasts a non-metallic composite toe that meets ASTM F2413-18 M I/75 C/75 EH standards, providing essential protection without the conductivity concerns associated with steel. Its Electrical Hazard (EH) protection is paramount for electricians, offering a reliable barrier against open electrical circuits. The full-grain, waterproof leather upper and a Danner Dry lining work in tandem to ensure excellent water resistance and breathability, keeping feet dry and comfortable.

Performance is a key attribute of the Vicious boot, emphasizing stability and lasting comfort. The Vibram Nisqually Arctic Grip outsole offers superior traction on wet and icy surfaces, a significant advantage in varying work conditions. The dual-density EVA and polyurethane midsole system provides adaptive cushioning and support, effectively reducing foot fatigue. The shank offers additional torsional stability. For electricians who prioritize non-metallic safety features, exceptional traction, and long-term comfort in challenging environments, the Danner Vicious presents a high-value, durable, and performance-driven footwear solution.

The Essential Protection: Why Electricians Need Specialized Work Boots

The rigorous demands of electrical work necessitate a specific type of footwear designed not only for comfort and durability but also for paramount safety. Electricians frequently encounter live electrical currents, hazardous environments with debris, and physically taxing conditions. Standard footwear is insufficient to mitigate these risks, making specialized work boots an indispensable component of an electrician’s personal protective equipment (PPE). These boots are engineered with specific features to shield the wearer from electrical hazards, provide superior grip on various surfaces, and offer the robust support required for long hours on their feet.

Practically, the primary driver for electricians to invest in dedicated work boots centers on electrical hazard (EH) protection. These boots are constructed with non-conductive materials and undergo rigorous testing to ensure they can withstand a significant electrical charge, significantly reducing the risk of electrocution. Additionally, many electrical environments present trip hazards, falling objects, and slippery surfaces. Work boots designed for electricians often feature slip-resistant outsoles for enhanced traction and composite or steel toes for protection against crushing injuries. The durability of these boots is also a crucial practical consideration, as they are subjected to constant wear and tear in demanding conditions, requiring materials that can withstand abrasion, moisture, and chemical exposure.

Economically, the purchase of high-quality work boots represents a prudent investment for electricians. The cost of a serious electrical injury, ranging from medical expenses and lost wages to potential long-term disability and legal ramifications, far outweighs the initial expenditure on appropriate footwear. By preventing accidents, specialized work boots contribute to a reduction in workplace downtime and insurance claims, fostering a more stable and productive work environment for both the individual and their employer. Furthermore, durable boots minimize the frequency of replacements, offering a cost-effective solution over time compared to constantly purchasing less robust footwear.

Ultimately, the need for specialized work boots for electricians is a multi-faceted requirement driven by an imperative for personal safety, operational efficiency, and long-term economic viability. The unique hazards inherent in electrical work demand footwear that goes beyond basic comfort and protection. Investing in EH-rated, durable, and supportive work boots is not merely a matter of compliance but a fundamental necessity for electricians to perform their duties safely, effectively, and with the confidence that their most critical protective gear is up to the task.

Key Features to Consider for Electrician Work Boots

When selecting work boots for an electrician, several critical features demand careful consideration to ensure both safety and comfort on the job. Foremost among these is electrical hazard (EH) protection. EH-rated boots are designed with non-conductive soles and heels, preventing electrical current from passing through the boot and into the wearer. This rating, often indicated by a yellow triangle or the letters “EH” on the boot, is non-negotiable for anyone working near live electrical circuits. Beyond EH protection, slip-resistant outsoles are paramount. Electricians often work on various surfaces, some of which can become slick with oil, water, or dust. A well-designed tread pattern and rubber compound can significantly reduce the risk of slips and falls, a common cause of workplace injuries.

Another crucial element is ankle support. Many electrical tasks involve climbing ladders, navigating uneven terrain, or working in cramped spaces. Boots with adequate ankle support, typically achieved through a higher shaft and reinforced lacing systems, help prevent sprains and strains. However, it’s important to strike a balance; excessive stiffness can hinder mobility. Materials also play a vital role. Leather is a popular choice due to its durability, water resistance, and ability to mold to the wearer’s foot over time. However, certain synthetic materials can offer lighter weight and enhanced breathability. Insulation is another factor, particularly for electricians working in colder climates or unheated environments, though excessive insulation can lead to overheating in warmer conditions.

Comfort, while often overlooked in favor of purely safety-focused features, is equally important for productivity. A boot that causes discomfort will inevitably distract an electrician and can lead to reduced performance and increased fatigue. This includes factors like cushioning, arch support, and a well-fitting interior. Many high-quality electrician boots incorporate features like cushioned insoles, supportive midsoles, and moisture-wicking linings to enhance long-term wearability. Finally, the overall construction and durability of the boot are essential. Electricians need boots that can withstand the rigors of daily use, including exposure to chemicals, abrasions, and impact. Reinforced stitching, durable hardware, and robust sole attachment methods contribute to a longer lifespan and consistent protection.

Understanding Electrical Hazard (EH) Ratings and Standards

The electrical hazard (EH) rating is a critical safety specification for any work boot intended for electricians. This rating signifies that the boot’s sole and heel are constructed with specific non-conductive materials that can withstand a secondary, low-level electrical shock. The standard governing EH-rated footwear in the United States is ASTM F2413, which outlines the testing procedures and minimum performance requirements. Boots meeting this standard are designed to provide a degree of protection against accidental contact with live electrical circuits, acting as a barrier to prevent current from flowing through the wearer to the ground.

It’s crucial to understand that EH-rated boots are not a substitute for proper personal protective equipment (PPE) or adherence to electrical safety protocols. They offer a supplementary layer of protection, and electricians must always assume that all circuits are live until proven otherwise. The EH rating is typically indicated by a yellow triangle symbol on the boot or its packaging, along with the letters “EH.” This marking signifies that the boot has been tested and certified to meet the ASTM F2413 standard for electrical hazard protection. Without this designation, a boot should not be considered suitable for work environments with potential electrical exposure.

The materials used in EH-rated boots are specifically chosen for their dielectric properties. This means they resist the flow of electricity. Common materials include specialized rubber compounds and certain types of non-conductive plastics. The construction of the boot also plays a role; for example, the absence of metal shanks or reinforcement plates within the sole can further enhance its insulating capabilities. It’s important to note that the EH protection of a boot can be compromised by wear and tear, damage to the sole, or the presence of conductive materials like metal filings or liquids that can create a path for electricity. Regular inspection and maintenance are therefore vital to ensure continued EH performance.

Maintaining Your Electrician Work Boots for Longevity and Safety

Proper maintenance is crucial for ensuring that your electrician work boots remain safe, effective, and comfortable over their lifespan. Neglecting care can not only shorten their durability but also compromise the very safety features that make them suitable for the profession. Regular cleaning is the foundational step. After each day’s use, it’s advisable to remove any accumulated dirt, dust, or debris from the boots, both inside and out. This can be done with a stiff brush or a damp cloth. For leather boots, specialized leather cleaners can be used to remove stubborn grime without damaging the material.

Beyond basic cleaning, conditioning leather boots is essential to prevent drying, cracking, and water damage. Apply a quality leather conditioner periodically, following the product’s instructions. This helps to maintain the leather’s flexibility and water-repellent properties. For boots with other materials, consult the manufacturer’s recommendations for appropriate cleaning and conditioning agents. Inspecting your boots for wear and tear is another vital aspect of maintenance. Pay close attention to the soles for any signs of excessive wear, cuts, or embedded objects. Damaged soles can significantly reduce slip resistance and compromise electrical hazard protection.

Check the laces and eyelets for any fraying or damage that could affect the fit and support of the boot. The stitching should also be examined for any loose threads or signs of separation. If you notice any significant damage, especially to the electrical hazard rated components, it is imperative to replace the boots rather than attempt repairs, as compromised EH protection can be extremely dangerous. Finally, proper storage can also contribute to the longevity of your work boots. Store them in a cool, dry place away from direct sunlight, and avoid leaving them in damp conditions, which can promote mildew and material degradation.

Innovations and Emerging Trends in Electrician Footwear

The field of work boot design is continually evolving, with manufacturers consistently striving to enhance safety, comfort, and durability through technological advancements. One significant trend is the integration of advanced cushioning and support systems. Modern electrician boots often feature multi-density insoles, ergonomic footbeds, and shock-absorbing midsoles that mimic the comfort found in athletic footwear. These innovations aim to reduce foot fatigue and provide better arch support, particularly for electricians who spend extended periods on their feet. This focus on biomechanics contributes to improved worker well-being and productivity.

Another area of innovation lies in the materials science sector. New composite materials are being developed for toe protection, offering the same level of impact resistance as traditional steel toes but at a significantly reduced weight. This not only enhances comfort but also helps to prevent the boot from conducting electricity if it were to come into contact with live wires. Similarly, advancements in waterproof and breathable membranes, such as Gore-Tex and similar technologies, are being incorporated into boot linings. These materials allow moisture vapor from the foot to escape while preventing external water from entering, keeping feet dry and comfortable in varying conditions.

The trend towards more versatile designs is also evident. While EH protection remains paramount, manufacturers are also focusing on creating boots that are suitable for a wider range of work environments. This includes incorporating features like enhanced grip on smooth surfaces, oil and chemical resistance, and improved flexibility for ease of movement. Furthermore, the aesthetic appeal of work boots is not being ignored. While functionality is the priority, sleeker designs and more contemporary color palettes are appearing, catering to electricians who value both performance and a professional appearance. The ongoing push for sustainability is also influencing material choices and manufacturing processes, with an increasing use of recycled and eco-friendly components.

The Best Work Boots for Electricians: A Comprehensive Buying Guide

The role of an electrician is inherently demanding, requiring a unique blend of technical skill, physical dexterity, and an unwavering commitment to safety. Navigating construction sites, attics, crawl spaces, and often precarious work environments necessitates footwear that is not merely protective but specifically engineered to address the distinct hazards faced by this profession. From potential electrical hazards to the rigors of daily wear and tear, the selection of appropriate work boots is paramount. This guide aims to provide a data-driven analysis of the crucial factors electricians should consider when selecting their ideal work boots, ultimately identifying the best work boots for electricians that balance safety, comfort, durability, and regulatory compliance.

1. Electrical Hazard (EH) Protection

The most critical feature for any electrician’s work boots is robust Electrical Hazard (EH) protection. This rating signifies that the boots are manufactured with non-conductive materials that can withstand the rigors of a secondary electrical shock. EH-rated boots are designed to act as an insulator, preventing a dangerous electrical current from reaching the wearer’s body through the ground. The American Society for Testing and Materials (ASTM) establishes the standards for this protection, with boots typically tested to withstand 18,000 volts at 60Hz for one minute without leakage. This is a critical safety measure, as accidental contact with live electrical components can be fatal. When evaluating the best work boots for electricians, always look for the ASTM F2413-18 EH rating prominently displayed on the boot or its packaging. This ensures a quantifiable level of protection against electrical shocks, a non-negotiable aspect of the profession.

The practical impact of EH protection cannot be overstated. In environments where downed power lines, faulty wiring, or unexpected energized circuits are present, these boots serve as a vital line of defense. The materials used in EH-rated boots are specifically chosen for their insulating properties, meaning they are manufactured without any conductive metal components, such as steel shanks or eyelets. This deliberate design choice minimizes the risk of creating a pathway for electricity to flow through the wearer. Furthermore, the soles are typically made from specialized rubber compounds that are tested for their dielectric strength, providing a reliable barrier against stray voltage.

2. Slip Resistance

Electricians often work on a variety of surfaces that can become slippery, including wet concrete, oily floors, and uneven terrain. Consequently, the outsole of their work boots must offer exceptional slip resistance to prevent falls, which can lead to serious injuries. OSHA (Occupational Safety and Health Administration) regulations emphasize the importance of preventing workplace accidents, and slips are a common cause of injuries across many industries, including electrical work. Work boots designed for electricians will typically feature aggressive tread patterns with deep lugs and a specialized rubber compound that maximizes grip.

The effectiveness of slip resistance is often measured by the outsole’s coefficient of friction against various surfaces. While specific industry standards for slip resistance in footwear are complex, reputable boot manufacturers will often indicate their outsole’s performance on different surfaces like oil-soaked or wet floors. Brands that invest in proprietary outsole technologies, such as specific rubber formulations or unique tread designs, often provide demonstrably better traction. When considering the best work boots for electricians, prioritize boots with outsoles that have a proven track record of superior grip, especially in environments where spills or moisture are common. This proactive approach to slip prevention can significantly reduce the risk of accidents that could lead to more severe consequences, including electrocution or impact injuries from falls.

3. Comfort and Support

The demands of an electrician’s job mean spending long hours on their feet, often in challenging positions. Therefore, comfort and adequate support are not mere luxuries but essential components for productivity and long-term well-being. Poorly fitting or unsupportive boots can lead to foot fatigue, blisters, arch pain, and even more serious musculoskeletal issues like plantar fasciitis. High-quality work boots designed for electricians incorporate features such as cushioned insoles, supportive midsoles, and well-designed arch support to absorb shock and distribute pressure evenly across the foot.

Data from ergonomic studies consistently shows that proper footwear can significantly reduce the incidence of foot-related pain and fatigue. Many of the best work boots for electricians feature advanced cushioning technologies, such as EVA (ethylene-vinyl acetate) or polyurethane midsoles, which provide superior shock absorption compared to traditional materials. Furthermore, features like shock-absorbing heel cups and contoured footbeds contribute to a more natural gait and reduce strain on the feet and lower legs. The ability of a boot to maintain comfort throughout a demanding workday directly impacts an electrician’s focus and ability to perform intricate tasks safely.

4. Durability and Construction

Electricians work in demanding environments that can quickly degrade lower-quality footwear. The best work boots for electricians are constructed from high-quality, durable materials and built to withstand the abrasion, impacts, and environmental exposures common to job sites. This includes robust leather uppers, reinforced stitching, and durable outsole materials. The lifespan of a pair of work boots is a critical consideration for both economic and practical reasons. Investing in a well-made pair means fewer replacements and reliable protection over an extended period.

The construction methods employed by boot manufacturers play a significant role in durability. Goodyear welt construction, for example, is a highly regarded method that allows for resoling, extending the life of the boot considerably. Other durable features include reinforced toe caps to protect against impacts, abrasion-resistant heel counters, and triple-stitched seams in high-stress areas. The quality of the leather used is also paramount; full-grain leather is known for its exceptional strength and resistance to wear and tear. When looking for the best work boots for electricians, consider boots that are built to last, often indicated by the quality of materials and construction techniques. This resilience ensures that the boots can consistently provide the necessary protection and support throughout their intended lifespan.

5. Fit and Sizing

A proper fit is fundamental for both comfort and safety. Ill-fitting boots can lead not only to discomfort but also to compromised performance and an increased risk of injury. Work boots that are too tight can restrict circulation and cause pressure points, while boots that are too loose can lead to rubbing, blisters, and instability, increasing the likelihood of trips and falls. The anatomical shape of the foot varies, and therefore, finding the best work boots for electricians involves understanding one’s foot shape and choosing a brand or model that offers a consistent and reliable fit.

It is advisable to try on boots at the end of the day when feet are typically at their largest. Wearing the type of socks that will be used on the job is also crucial for an accurate assessment of the fit. Manufacturers often provide detailed sizing charts and recommend trying on boots to ensure adequate toe room and heel lock. The boot should feel snug but not constrictive, with no pinching or excessive movement. Many experienced electricians find that certain brands consistently fit their foot shape better than others, highlighting the importance of personal experience and trying different options to identify the ideal fit.

6. Waterproofing and Breathability

Electricians may encounter a range of weather conditions, from rain and snow to humid environments. Therefore, work boots with appropriate waterproofing are essential to keep feet dry and comfortable, preventing issues like athlete’s foot and maintaining insulation in colder temperatures. However, it is equally important for these boots to remain breathable to prevent excessive moisture buildup from perspiration, which can also lead to discomfort and skin problems. A balance between waterproof protection and breathability is key to optimal performance.

Many modern work boots achieve this balance through the use of waterproof yet breathable membranes, such as Gore-Tex or similar proprietary technologies. These materials are designed to allow water vapor (sweat) to escape from the boot while preventing liquid water from entering. The upper materials themselves, such as treated leathers, also contribute to the boot’s ability to resist water penetration. When evaluating the best work boots for electricians, look for boots that clearly state their waterproofing capabilities and are constructed with materials known for their breathability. This dual functionality ensures that an electrician’s feet remain dry and comfortable regardless of the external conditions, a vital consideration for sustained performance and well-being on the job.

FAQ

Why are electrical hazard (EH) rated boots essential for electricians?

Electrical Hazard (EH) rated boots are critical safety equipment for electricians because they are designed to provide a secondary layer of protection against accidental contact with live electrical circuits. These boots are constructed with non-conductive materials, specifically the soles and heels, which are tested to withstand a significant electrical shock. The ASTM F2413 standard, which governs protective footwear in the United States, outlines specific requirements for EH protection, including resistance to electrical shock of 18,000 volts at 60Hz for one minute. This means the boots are intended to reduce the flow of electricity through the wearer to the ground, offering a crucial safeguard in environments where the risk of electrocution is present.

The importance of EH rating stems from the inherent dangers of working with electricity. While electricians are trained to de-energize circuits and follow strict safety protocols, unexpected energized parts or accidental contact can occur. EH rated boots act as a vital barrier, offering a crucial margin of safety in such unforeseen circumstances. It’s important to understand that these boots are not a substitute for proper lockout/tagout procedures or insulated tools, but rather a complementary safety measure. Their presence significantly reduces the potential for a serious or fatal electrical injury by preventing the body from becoming a conductor in a hazardous situation.

What is the difference between EH and SD (Static Dissipative) rated boots?

Electrical Hazard (EH) rated boots are designed to provide protection from accidental contact with live electrical circuits by acting as an insulator. As previously mentioned, they are tested to withstand a high voltage for a specific duration, significantly reducing the risk of electrocution. The materials used in the construction of EH boots, particularly the soles and heels, are specifically chosen for their non-conductive properties. This makes them ideal for situations where the primary concern is protection from electrical shock originating from external sources.

Static Dissipative (SD) rated boots, on the other hand, are engineered to safely dissipate static electricity that can build up on the wearer’s body. This dissipation occurs at a controlled rate, preventing the accumulation of a significant static charge. SD boots are essential in environments where static discharge could ignite flammable materials or damage sensitive electronic components, such as working with fine circuitry or in petrochemical plants. While they offer some electrical resistance, it is not the same level of protection as EH boots; their primary function is to manage static electricity, not to insulate from live circuits.

Are steel toe caps always necessary for electricians, or are composite toes an acceptable alternative?

Steel toe caps have historically been the standard for impact protection in work boots due to their durability and cost-effectiveness. They offer robust protection against falling objects and compression hazards, meeting industry standards like ASTM F2413 for impact (I) and compression (C) resistance. However, steel toes have certain drawbacks, including their conductivity. This conductivity can be a concern for electricians working in environments with potential electrical hazards, as metal can conduct electricity.

Composite toe caps, typically made from materials like Kevlar, carbon fiber, or specialized polymers, offer a viable and often preferable alternative for electricians. These materials are non-conductive, providing the same level of impact and compression protection as steel toes without the risk of conducting electricity. This makes them an excellent choice for electricians who need foot protection while minimizing the risk of electrical hazards. Many modern work boots designed for electricians feature composite toes specifically to address this safety consideration, ensuring comprehensive protection in their specialized work environment.

What are the most important features to look for in work boots for an electrician?

When selecting work boots for an electrician, the paramount feature is Electrical Hazard (EH) protection, meeting the ASTM F2413 standard. This ensures a crucial layer of safety against accidental electrical contact. Beyond EH rating, durability and comfort are vital for prolonged wear in demanding conditions. Look for boots constructed with high-quality, oil-resistant, and slip-resistant outsoles to provide reliable traction on various surfaces, including oily or wet environments often encountered on job sites.

Another critical consideration is the toe protection. Composite toe caps are highly recommended as they offer robust protection against impacts and compression without being conductive, unlike steel toes. Furthermore, ankle support is essential for stability, especially when climbing ladders or navigating uneven terrain. The materials used in the boot’s upper should be breathable yet protective; leather is a common and effective choice. Lastly, consider the boot’s weight and flexibility, as these factors significantly impact comfort and reduce fatigue throughout a long workday.

How important is slip resistance for electrician work boots?

Slip resistance is exceptionally important for electrician work boots, as job sites can present a variety of slick or uneven surfaces, including wet floors, oil spills, or dusty concrete. Excellent traction from the outsole prevents slips, trips, and falls, which can lead to serious injuries. For electricians, a fall can be particularly dangerous if it results in contact with energized equipment or from a significant height. Slip-resistant soles are engineered with specific tread patterns and rubber compounds that maximize grip on different surfaces.

The importance of slip resistance is underscored by the potential consequences of a slip. A fall can cause immediate injuries like sprains, fractures, or head trauma. For an electrician, a slip could also lead to unintended contact with live wires or components, exacerbating the danger. Therefore, selecting boots with a proven track record of slip resistance, often indicated by ratings such as those adhering to ASTM F344, is a non-negotiable aspect of ensuring safety and maintaining productivity on the job.

Should I prioritize waterproofing or breathability in my electrician work boots?

The choice between prioritizing waterproofing and breathability for electrician work boots often depends on the specific working conditions and climate. If you frequently work in wet environments, such as outdoors during inclement weather or in areas prone to water exposure, waterproof materials like Gore-Tex or treated leather are highly beneficial. Waterproofing keeps your feet dry, preventing discomfort, blisters, and potential fungal infections that can arise from prolonged dampness.

However, overly waterproof boots can sometimes compromise breathability, leading to sweaty feet in warmer conditions. Conversely, highly breathable boots may not offer adequate protection against water intrusion. Many modern work boots achieve a balance through advanced materials and construction techniques, offering good water resistance without sacrificing excessive breathability. It is advisable to consider the typical conditions you encounter most often. If your work predominantly involves dry, indoor environments, breathability might be a higher priority for comfort, while consistently wet conditions necessitate robust waterproofing.

How long should I expect my electrician work boots to last, and what maintenance is required?

The lifespan of electrician work boots can vary significantly depending on the quality of the materials, the intensity of usage, and the level of maintenance they receive, but typically, a well-maintained pair of quality work boots can last between 6 months to 2 years. High-quality boots constructed with durable leather uppers, robust stitching, and well-bonded soles are designed for longevity. Regular inspection for wear and tear, particularly on the soles, seams, and any electrical hazard protective elements, is crucial for identifying when replacement is necessary.

Proper maintenance is key to extending the life of your work boots and ensuring their continued safety performance. This includes cleaning the boots regularly to remove dirt, debris, and any potentially damaging chemicals. For leather boots, conditioning them periodically helps to prevent drying and cracking, which can compromise their integrity and protective qualities. It’s also important to allow boots to dry thoroughly between uses and avoid storing them in damp conditions. For EH rated boots, it is advisable to inspect the soles for any nicks, cuts, or embedded objects that could compromise their insulating properties, as damage to the sole can render the EH rating ineffective.

Conclusion

Selecting the optimal footwear for electricians is a critical decision impacting both safety and daily performance. This review and buying guide has underscored that the best work boots for electricians must prioritize electrical hazard (EH) protection, offering a robust barrier against potential electrical currents. Beyond EH certification, features such as non-conductive materials in the sole and heel construction, slip-resistant outsoles for stable footing on various surfaces, and durable yet flexible uppers that allow for unhindered movement are paramount. Comfort, facilitated by supportive insoles and breathable linings, is also essential for electricians who spend extended periods on their feet.

Ultimately, the ideal work boot for an electrician is a synergistic blend of safety compliance, practical functionality, and enduring comfort. While various models offer distinct advantages, a consistent thread throughout the analysis points towards boots that integrate advanced EH protection with long-lasting durability and ergonomic design. Prioritizing these attributes ensures that electricians can confidently and comfortably navigate the demanding environments of their profession, minimizing risk and maximizing productivity throughout their workday.

Based on the comprehensive evaluation of safety certifications, material integrity, user comfort, and job-specific demands, we recommend electricians invest in work boots that prominently feature ASTM F2413 EH ratings and are constructed with non-metallic shanks and eyelets. Brands offering models with Vibram soles for superior traction and moisture-wicking linings for enhanced comfort during prolonged use represent sound investments, contributing directly to both occupational safety and overall job satisfaction.